-

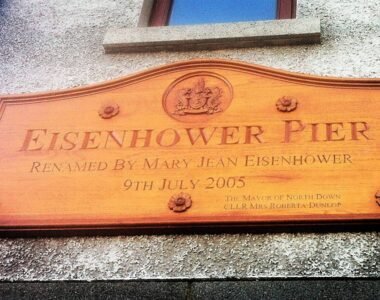

Bangor Marina Bangor, Northern Ireland

-

Conwy Marina Conwy, North Wales, Wales

-

Deacons Marina River Hamble, Southampton, England

-

East Cowes Marina East Cowes, Isle of Wight, England

-

Haslar Marina Haslar, Portsmouth Harbour, England

-

Penarth Marina Penarth, Cardiff, Wales

-

Portishead Marina Portishead, Bristol, England

-

Portland Marina Portland, Dorset, England

-

Rhu Marina Rhu, Firth of Clyde, Scotland

-

Royal Quays Marina Royal Quays, North Shields, England

-

Weymouth Marina Weymouth, Dorset, England

4th March 2021

Deacons

Bespoke mould and finish of a new bathing platform for a Crownline 270.

The original platform was moulded to fit profile and locators on the yachts transom. So the splash moulding was taken from the existing platform to build the new mould so that it fitted perfectly. After completion/preparation of the splash moulding, a reverse plug/pattern mould was constructed to include the surrounding flange of the platform as well as a recess for a Flexiteek inlay to be added later.

Once the mould was completed it was waxed to allow release of the final part, before laying up in a custom colour matched gelcoat, followed by several layers of glass fibre and polyester resin. A plywood core and stringers was added to increase the stiffness of the platform.

Once released from the mould, the reverse plug/pattern was test fitted to the yacht, ready for finishing and polishing. Once finished the platform was fitted to the yacht, and trimmed in situ.

Next, we had to create the wings to the sides of the platform. A wing moulding was built in situ on the port and starboard sides to fair in to the platform. This was gel coated to match the bathing platform and then fitted, with a final polish of the whole platform to finish.